A new era of lean; supported by real-time data

Although someone can consider digital transformation as a competitor or even replacement of lean, it’s actually the other way around: going digital leverages lean and increases its positive impact.

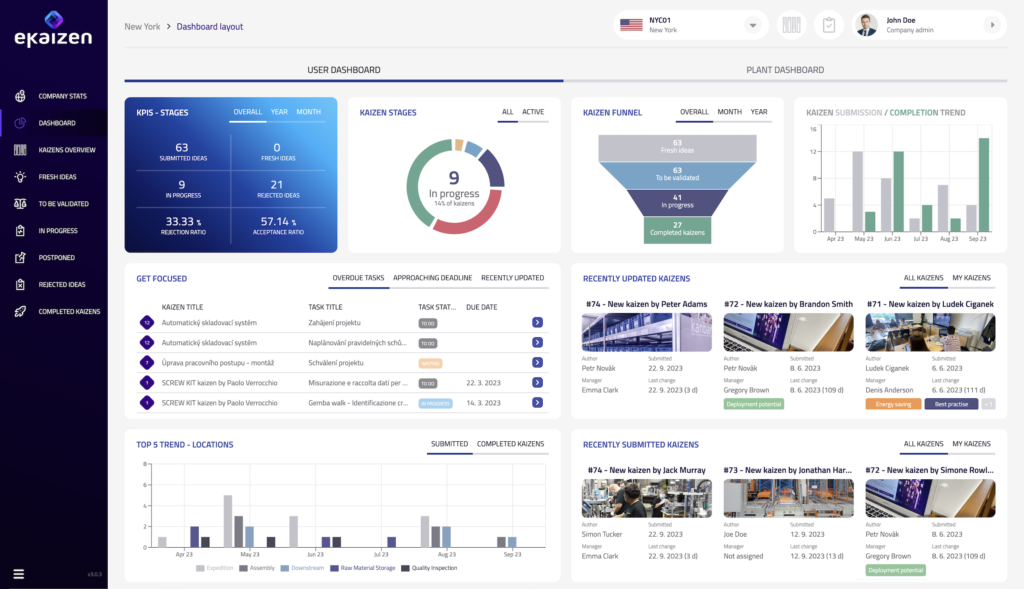

eKaizen provides you with accurate information and helps you achieve lean goals more efficiently. The right data, presented to the right people in real-time, enables a high degree of operational flexibility – one you probably wouldn’t be able to reach using only traditional lean methods.

Fully digitized CI

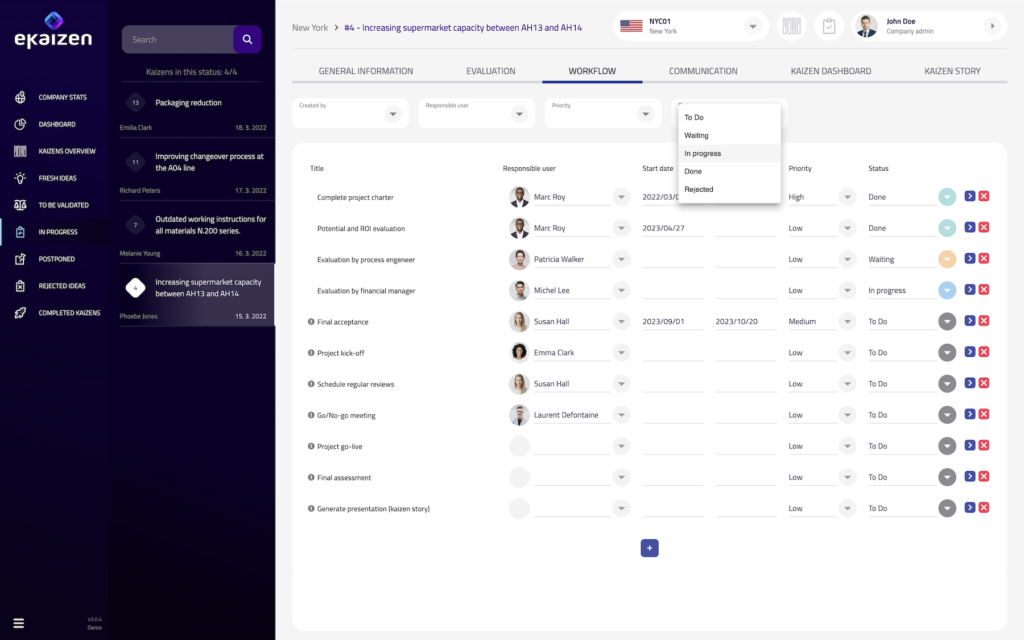

eKaizen fully digitizes all processes related to continuous improvement. Anybody who participates in improvement initiatives has their own set of tools to make their tasks as easy as possible. Idea authors, CI/OpEx leaders, department managers and company executives – each role needs to perform different actions and make different decisions to turn ideas into successful projects. Connecting all teams and letting them work with a single source of data significantly increases the overall impact of improvements.

Waste elimination

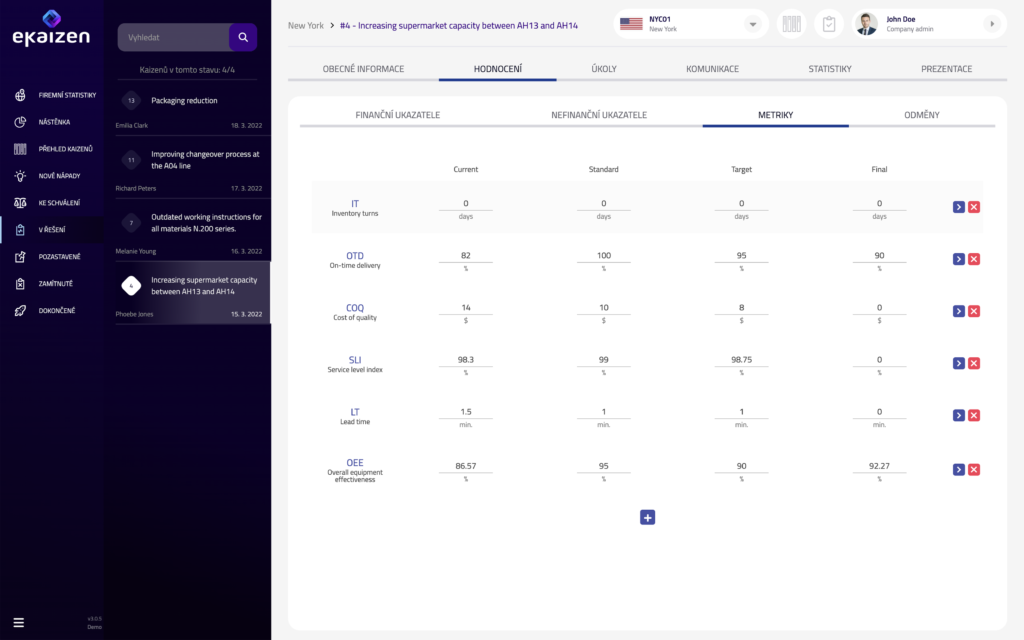

eKaizen helps you identify areas with the potential for waste elimination. The typical seven types of waste can be tracked for a single improvement as well as for a group of projects in order to better understand the trend. Features such as metric tracking allow you to measure waste elimination of ongoing projects with respect to predefined milestones or within certain time frames.

Data-driven decisions

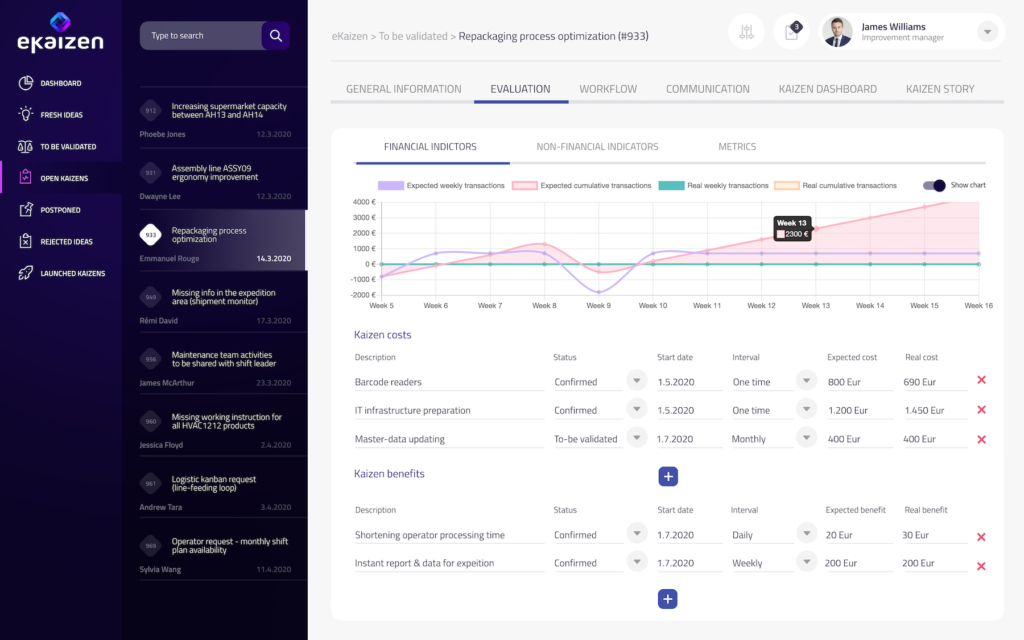

Evaluate projects based on real data. With eKaizen you can easily calculate the ROI of any improvement suggestions. Compare the expected and actual costs and savings, measure the impact of completed and ongoing projects, make predictions for the upcoming months. Track the relevant KPIs using milestones such as Current value, Target, Company standard, Achieved result, One-year evaluation etc. The management of your improvement initiatives has never been more accurate.